Clay sewer pipes have been a staple in plumbing systems for decades, particularly in older homes and buildings. Known for their durability and resistance to corrosion, these pipes have stood the test of time in many environments. However, as plumbing systems age or require modifications, it often becomes necessary to cut clay sewer pipes. This may be necessary for repairs to damaged sections, replacements with modern materials, or the installation of new connections to expand the system.

Cutting clay sewer pipes is a precise process that demands the proper tools and techniques to avoid unintended breakage or safety hazards. Using the right approach ensures the job is done efficiently and minimizes potential issues down the line. This article provides a comprehensive step-by-step guide on how to cut clay sewer pipe safely and effectively, offering invaluable insights for both professionals and DIY enthusiasts tackling plumbing challenges.

Understanding Clay Sewer Pipes

Clay sewer pipes have unique characteristics that make them both durable and challenging to work with. Understanding these properties is essential to handling them safely and effectively.

Properties of Clay Pipe

Clay pipes are known for their brittleness and significant weight. While they are resistant to corrosion and can last for decades under proper conditions, they are prone to cracking when mishandled. This fragility requires extra care during transportation, installation, or repairs. Additionally, their heavy composition makes them cumbersome, often requiring multiple people or specialized equipment for movement.

Where Clay Pipes Are Commonly Found

These pipes are a common feature in older homes, particularly those constructed in the early 20th century, and are also frequently used in municipal sewer systems. Their historical popularity stems from their long lifespan and resistance to chemical damage. However, modern materials have replaced them mainly in contemporary plumbing projects.

Challenges When Working With Clay

When dealing with clay pipes, cracking is one of the biggest risks, as even minor impacts can cause significant damage. Cutting and handling these pipes can also produce fine dust particles, posing health hazards if proper precautions are not followed. Their weight further complicates the process, requiring careful planning for lifting and positioning.

When Cutting Is Necessary

Cutting clay pipes is often necessary when making repairs, connecting them to PVC piping, or replacing damaged sections. The process allows plumbers to modify or expand existing systems while ensuring the integrity and functionality of the pipeline. Proper techniques and tools are essential for achieving clean, precise cuts without causing additional damage.

Safety Precautions and Preparations

When working with clay pipes, taking proper safety precautions and making thorough preparations is essential to ensure a successful and hazard-free project.

Personal Protective Equipment (PPE)

Wearing the appropriate PPE is crucial to protect yourself from potential injuries. Always use eye protection, such as safety goggles, to shield your eyes from flying debris during the cutting process. Heavy-duty gloves are necessary to prevent cuts or abrasions from sharp edges.

A dust mask or respirator should be worn to avoid inhaling fine particles, especially when cutting or grinding the pipe, as this can generate harmful silica dust. Additionally, hearing protection is recommended to reduce the risk of damage from loud power tools.

Worksite Preparation

Before starting, ensure the worksite is adequately prepared. Begin by clearing access to the pipe, removing any obstacles that might hinder movement or pose a tripping hazard. Secure your footing on stable ground to maintain balance during cutting or repair activities. Check for any live utilities nearby, such as electrical lines or active plumbing, and turn them off if necessary to prevent accidents.

Pipe Inspection

A careful inspection of the clay pipe is essential before proceeding. Look for structural weaknesses, cracks, or irregular shapes that could affect the cutting process or compromise the pipe’s integrity. Address these issues beforehand to improve the outcome of your repairs or modifications.

Tools You Can Use to Cut Clay Sewer Pipe

When working with clay sewer pipes, selecting the right tool is crucial for efficient and safe cutting. Below are commonly used tools and a comparison of their strengths and drawbacks:

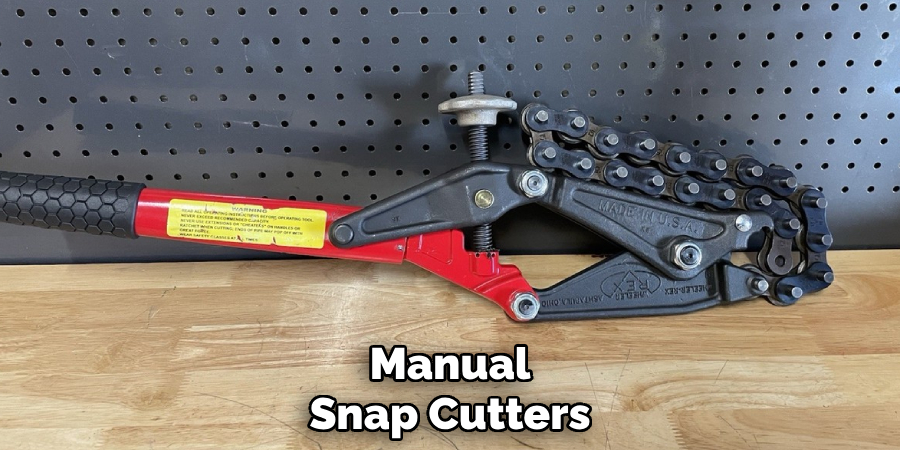

Manual Snap Cutters

- How They Work: A manual snap cutter uses a chain fitted with cutting wheels. The chain wraps around the pipe, and by tightening it, the wheels apply pressure, snapping the pipe cleanly.

- Best For: This tool excels in underground areas or locations with tight access where power tools may not fit or be practical.

Angle Grinder with Diamond Blade

- How They Work: An angle grinder fitted with a diamond blade can make precise, clean cuts through clay piping.

- Best For: It is ideal for situations that demand accuracy, but note that it requires electricity and generates significant dust. Always use appropriate safety gear, such as goggles and a mask, while operating this tool.

Reciprocating Saw (Sawzall)

- How They Work: A reciprocating saw equipped with a carbide-tipped or diamond grit blade can cut through clay pipes effectively.

- Best For: This tool is versatile and user-friendly, suitable for many cutting scenarios. It offers flexibility when electricity or workspace is limited.

Pipe Cutter vs. Grinder: Pros and Cons

When choosing between a pipe cutter and a grinder, consider these factors:

- Speed: Pipe cutters generally work faster in small spaces, while grinders may take more time but offer precision.

- Noise: Grinders are noisier than manual cutters.

- Dust: Grinders create more dust compared to the relatively cleaner operation of manual cutters.

- Portability: Manual cutters are easier to transport and operate in confined spaces, whereas grinders require power and safety equipment.

- Finish Quality: Grinders tend to leave smoother edges, while snap cutters may cause slight unevenness depending on the pipe.

Select a tool based on your project’s specific needs and conditions for optimal results.

How to Cut Clay Sewer Pipe: Step-by-Step Guide

Step 1: Mark the Cut Line

Begin by marking a clear, straight cut line on the pipe. Use chalk or a marker to ensure the line is visible and easy to follow during the cutting process. Accuracy at this stage will help achieve a clean and precise cut.

Step 2: Secure the Pipe

Stabilize the pipe to prevent movement during cutting. Use wedges, pipe cradles, or any suitable support to immobilize the pipe securely. Ensuring the pipe is steady minimizes the risk of inaccurate cuts and potential injuries.

Step 3: Choose the Tool and Begin the Cut

Select the appropriate tool for your project.

- Manual Cutter: Wrap the chain cutter evenly around the pipe along the marked line. Gradually tighten the chain while maintaining alignment until the pipe snaps cleanly.

- Grinder or Saw: Align the blade with the marked line and begin cutting carefully. For larger pipes, you may need to rotate around the pipe to complete the cut evenly.

Step 4: Finish and Clean the Cut

Once the pipe is cut, inspect the edges for any roughness or irregularities. Use a rasp or sanding block to smooth the edges, ensuring a clean finish that is safe to handle and ready for installation.

Step 5: Inspect the Cut Ends

Carefully examine the cut ends for cracks, chips, or breakage. Even minor defects can compromise the pipe’s sealing ability. Please address any issues to ensure the pipe functions properly in its intended application.

Tips for Making Clean, Safe Cuts

Avoid Rushing

Take your time when cutting pipes to ensure precision. Rushing can lead to mistakes, such as uneven cuts or cracking. A slow and steady approach minimizes the risk of misalignment and ensures the integrity of the pipe.

Keep Tools Sharp and Blades Fresh

Using sharp tools and fresh blades is essential for making clean cuts. Dull tools not only increase cutting time but can also result in jagged edges or an inaccurate cut. Regularly inspect and replace tools to ensure optimal results.

Keep the Area Wet (if using a Grinder)

If you are using a grinder, keeping the area wet is crucial. Water helps reduce dust generation and keeps the blade cool, preventing overheating. This creates a safer working environment and promotes smoother cuts.

Cut All the Way Around

For thicker pipes, it is often necessary to cut incrementally from multiple angles. By cutting all the way around, you ensure an even break and reduce the risk of deforming the pipe. This technique is particularly beneficial for materials like PVC or metal, which require more precision.

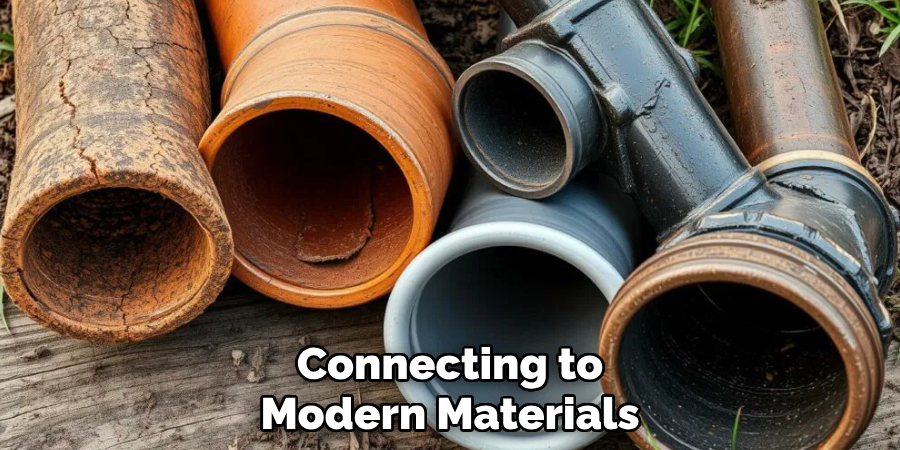

Connecting to Modern Materials After the Cut

When transitioning from older pipes to modern materials like PVC or ABS, it’s important to select the right connectors for a secure and effective join. No-hub (Fernco) couplings or rubber transition sleeves are commonly used for this purpose as they provide a reliable seal and flexibility in alignment.

Checking for Proper Alignment

Proper alignment is critical to ensure leak-free connections and smooth fluid flow through the pipe system. Misaligned pipes can lead to stress on the joints and potential leaks over time, so take extra care during the fitting process.

Testing the Fit

Before applying any sealants or clamps, always dry-fit the connections first. This process helps confirm that all components fit together seamlessly. Once satisfied with the arrangement, proceed to secure the fitting using the appropriate clamps or adhesives, ensuring a durable and long-lasting connection.

Common Mistakes to Avoid

When working with pipe systems, several common mistakes can jeopardize the quality and safety of your project. One frequent error is not wearing proper safety gear. Without adequate protection, you risk injury from flying debris, sharp edges, or harmful dust inhalation. Always wear safety goggles, gloves, and a dust mask to minimize these risks.

Another mistake is using the wrong tool for the situation. Selecting improper tools can damage the pipes or make the job unnecessarily difficult. Be sure to choose tools that match the size, material, and condition of your pipes for optimal efficiency and precision.

A third misstep is forcing the cut. Applying excessive pressure while cutting pipes can result in uneven edges or unpredictable breaks. Always use steady, controlled movements for a cleaner cut.

Finally, skipping the inspection can lead to hidden cracks going unnoticed. Even minor imperfections can turn into leaks or failures over time, so always conduct a thorough inspection before proceeding.

Conclusion

Learning how to cut clay sewer pipe effectively requires a careful approach to ensure successful results. Begin by understanding the type of pipe you’re working with and the specific requirements involved. Properly prepare the site to create a safe and structured environment. Select the right tool for the job, such as a pipe cutter or angle grinder, to achieve cleaner cuts.

Use proper technique with steady, controlled movements, and never rush the process. Safety, patience, and accuracy are essential throughout. For those unsure, practicing or consulting a professional is always recommended, especially for critical plumbing tasks.

Specialization:

- Master of wheel-throwing, hand-building, and advanced glazing techniques

- Focus on creating both functional pottery and decorative art pieces

Recognition:

- Celebrated by collectors and art enthusiasts for creating one-of-a-kind pieces that blend artistry with functionality

- Participates in local and national exhibitions, earning accolades for his innovative designs and craftsmanship

Passion:

- Deeply committed to exploring and pushing the boundaries of ceramic artistry

- Continuously experiments with new materials, firing techniques, and artistic concepts to evolve his craft

Personal Philosophy:

- Believes in the transformative power of art, aiming to evoke emotions and connections through his ceramic creations

- Advocates for sustainability in ceramics, using eco-friendly materials and practices whenever possible