Ceramic knives are sleek, lightweight, and incredibly sharp, making them a favorite choice for many home cooks and culinary enthusiasts. Unlike traditional metal knives, ceramic knives resist rust and maintain their edge far longer, owing to their ultra-hard zirconium dioxide composition. You may have seen these elegant objects online or in stores, but have you considered crafting one yourself?

Learning how to make a ceramic knife might seem like a challenging endeavor, but with the right tools, materials, and guidance, it’s a project that even beginners can undertake successfully. From shaping and refining the blade to creating a functional and ergonomic handle, this guide will walk you through every step to personalize a knife that combines functionality with an artisanal touch. Let’s get started!

Why Make Your Own Ceramic Knife?

Ceramic knives are not only practical but also a testament to elegant craftsmanship. Making your own allows you to understand the meticulous process behind these cutting-edge tools. Additionally, personalizing a ceramic knife lets you tailor its size, weight, and design to fit your specific needs in the kitchen and express your individual style.

Store-bought ceramic knives often come at a premium price, and they can lack the unique appeal of a handmade creation. By learning how to make a ceramic knife, you’re not only saving money but also acquiring a lasting skill. Whether you’re a hobbyist, a craft enthusiast, or someone interested in high-quality kitchen tools, this project offers an exciting way to combine creativity with functionality.

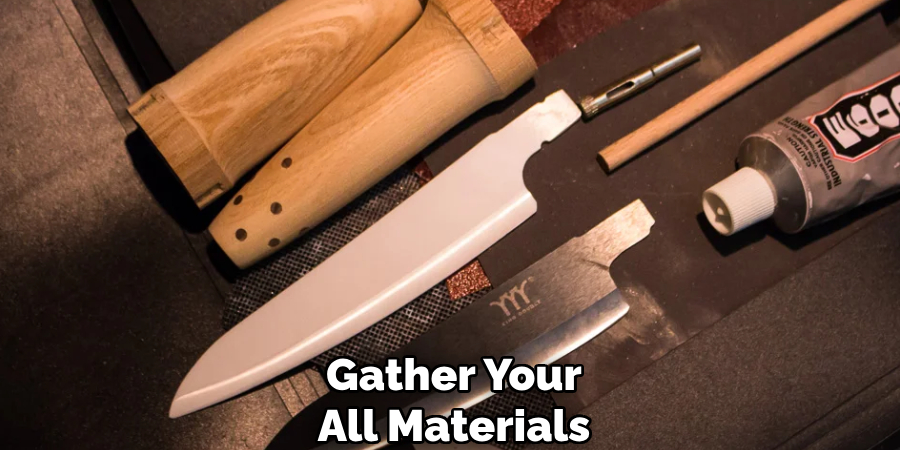

Materials Needed to Make a Ceramic Knife

Before beginning the process of crafting your ceramic knife, it’s important to gather all the necessary materials. Here’s a list of the basic items you’ll need:

- Ceramic blade blanks – These can be purchased online or from specialty craft stores and serve as the foundation of your knife.

- Handle material – Options are numerous, including wood, resin, or composite materials, depending on your preferred style and grip.

- Epoxy adhesive – A strong, food-safe epoxy is crucial for securely attaching the blade to the handle.

- Sandpaper or a rotary tool – Used to smooth and shape the handle for comfort and aesthetics.

- Protective gear – Safety goggles, gloves, and a dust mask are essential to protect yourself while working.

Once you have these materials, you’re ready to move on to the step-by-step process of assembling and customizing your ceramic knife. This preparation ensures that you have everything you need at hand, making the project more enjoyable and efficient.

Step-by-Step Guide on How to Make a Ceramic Knife

Creating a ceramic knife involves working with durable materials, precision cutting, and careful polishing. Follow the steps outlined below to craft a knife that’s both practical and beautiful.

Step 1: Gather Your Materials

To start the process, you’ll need zirconia ceramic blanks for the blade, a source of silicon carbide sandpaper or diamond sharpening stones, a basic template for the knife’s shape, and materials for the handle such as wood, plastic, or composite materials.

You’ll also need adhesive glue and a set of specialized tools, including a grinding wheel or belt sander with diamond attachments. Having all your materials and tools ready ensures that every stage flows seamlessly.

Step 2: Prepare a Suitable Workspace

Set up a workspace in a well-ventilated area, particularly if you’ll be using grinding wheels or power tools, as they can produce fine dust. Arrange your tools and safety equipment, such as glasses and gloves, to minimize risks. A clean, organized workspace not only enhances safety but also ensures greater accuracy throughout the project.

Step 3: Shape the Ceramic Blade Blank

Begin with the zirconia ceramic blank, which will form the blade’s core. Using a pre-made template or sketch, outline the desired knife shape onto the blank. Carefully cut or grind the material to match the shape, ensuring smooth and precise edges. Work slowly—ceramic is brittle, and any sudden pressure can lead to cracks.

Step 4: Refine the Blade’s Edges

Next, refine the edges of the blade using silicon carbide sandpaper or grinding tools with diamond abrasives. This step determines the sharpness and cutting efficiency of the knife. Focus on creating a crisp, symmetrical bevel along both sides of the blade, ensuring an even angle for optimal performance. Regularly inspect your progress and make gentle adjustments as needed.

Step 5: Smooth and Polish the Blade

To achieve a professional finish, polish the ceramic blade using progressively finer grits of diamond stones. This enhances its sharpness, reduces imperfections, and gives the blade a clean, mirror-like sheen. Take your time with this step—polishing is essential, not just for aesthetics but also for the knife’s long-term usability.

Step 6: Select and Shape the Handle

Choose a handle material that complements the ceramic blade while offering comfort and durability. Whether you opt for traditional wood or a modern composite, cut and shape the material using saws, sanders, or files. Design the handle to sit comfortably in your hand, as ergonomics play a huge role in the knife’s usability.

Step 7: Attach the Handle to the Blade

Once the handle is shaped, attach it securely to the blade using high-strength adhesive glue. For additional stability, consider embedding dowels or rivets into the handle. Allow the adhesive to cure fully following the manufacturer’s instructions. Proper attachment ensures that the blade is well-supported and safe to use.

Step 8: Final Sanding and Finishing

After assembling the knife, smooth any remaining rough edges on the handle and blade joint with fine sandpaper. This final step not only enhances the knife’s visual appeal but also ensures that it feels comfortable and seamless to hold. Thorough finishing makes a significant difference in the overall satisfaction of the finished product.

Step 9: Test the Knife

Carefully test the knife’s performance by cutting through soft materials like fruits and vegetables. Assess its grip, sharpness, and ease of handling. If needed, make minor adjustments or re-polish areas to achieve better balance and performance. With proper testing, you ensure that the knife is functional and ready for everyday use.

Step 10: Care for Your Ceramic Knife

Once complete, maintain your ceramic knife by avoiding tasks it’s not designed for, like cutting bones or frozen foods. Store it in a protective case or magnetic holder to prevent chipping. Proper care ensures longevity and preserves the effort you’ve put into crafting your unique tool.

Proper Maintenance Tips for Ceramic Knives

Taking care of your ceramic knife is essential to preserve its sharpness and durability. Always use a cutting board made of soft materials like wood or plastic to prevent the blade from chipping. Avoid using ceramic knives on hard or frozen foods, as the blade is more brittle compared to metal knives.

Clean the knife with warm water and mild soap immediately after use, and dry it thoroughly to prevent staining. It’s also recommended to store ceramic knives in a sheath, knife block, or on a magnetic strip to prevent accidental damage. Regularly inspect the blade for chips or cracks, and if needed, have it professionally sharpened, as ceramic blades require specialized tools for sharpening. Proper maintenance will ensure your ceramic knife remains an invaluable tool in your kitchen for years to come.

Frequently Asked Questions Section

What materials are used to make a ceramic knife?

Ceramic knives are crafted from zirconium dioxide (zirconia), a material known for its hardness and resistance to wear. The blades undergo sintering, a process of heating the zirconia to extreme temperatures, which enhances their durability and sharpness. For the handle, wood, plastic, or composites are commonly used to combine ease of use with a stylish finish.

How sharp are ceramic knives compared to metal ones?

Ceramic knives are often sharper than traditional metal knives straight out of the box. The hardness of zirconia allows the blade to maintain its sharp edge far longer than most steel counterparts. However, they are more brittle and require careful handling to prevent chipping or breaking.

Do I need specialized tools to make a ceramic knife?

Yes, crafting a ceramic knife requires tools designed for hard materials. Grinding wheels or belt sanders equipped with diamond abrasives are essential for shaping and refining the blade. Additionally, diamond sharpening stones are necessary for polishing and creating the final edge. Investing in these tools ensures precision and efficiency throughout the project.

Can I sharpen a ceramic knife at home?

Sharpening a ceramic knife at home is possible using diamond stones, but it requires patience and technique. Unlike steel knives, ceramic edges are more delicate and demand careful handling during sharpening. Alternatively, you can seek professional sharpening services for optimal results without risking damage.

How long does it take to make a ceramic knife?

The time required to make a ceramic knife depends on your experience level, the complexity of the design, and the tools available. For beginners, the process can take several days to a week, as precision and patience are key to achieving the desired finish. Experienced crafters may complete the project in a shorter time frame.

Conclusion

Making your own ceramic knife is a fascinating blend of science, art, and functionality. Through this guide, you’ve learned the step-by-step process of shaping, refining, and customizing a tool that adds both utility and craftsmanship to your kitchen.

Whether you’re a hobbyist, an aspiring artisan, or someone who simply enjoys DIY projects, mastering how to make a ceramic knife opens up a world of creative possibilities. With patience, precision, and the right tools, you can craft a knife that reflects your personal style while excelling at everyday tasks. Take the plunge into this rewarding project and enjoy the satisfaction of using a handmade creation in your culinary adventures!

Specialization:

- Master of wheel-throwing, hand-building, and advanced glazing techniques

- Focus on creating both functional pottery and decorative art pieces

Recognition:

- Celebrated by collectors and art enthusiasts for creating one-of-a-kind pieces that blend artistry with functionality

- Participates in local and national exhibitions, earning accolades for his innovative designs and craftsmanship

Passion:

- Deeply committed to exploring and pushing the boundaries of ceramic artistry

- Continuously experiments with new materials, firing techniques, and artistic concepts to evolve his craft

Personal Philosophy:

- Believes in the transformative power of art, aiming to evoke emotions and connections through his ceramic creations

- Advocates for sustainability in ceramics, using eco-friendly materials and practices whenever possible