Ceramic fuses play a vital role in safeguarding electrical devices and systems from dangerous overcurrents and short circuits. Found in everything from household appliances and vehicles to electronic equipment, these fuses are specifically designed to interrupt the flow of electricity when a fault occurs, preventing damage and reducing fire risk. However, when a ceramic fuse does its job and “blows,” it’s not always immediately obvious, and continued operation without a functioning fuse can damage your equipment or pose safety hazards.

Blown fuses are commonly encountered during power surges, equipment malfunctions, or after a device has drawn more current than the fuse was rated to handle. Users often notice problems when devices won’t power on or operate erratically, leaving them to wonder about the root cause.

If you find yourself facing an unresponsive device or experiencing intermittent electrical issues, knowing how to tell if a ceramic fuse is blown becomes an essential skill. This article offers a step-by-step guide on how to accurately diagnose a blown ceramic fuse, outlining everything from identifying visual symptoms to using a multimeter for precise testing. Whether you’re tackling a home repair or troubleshooting a technical issue at work, you’ll find clear, actionable advice here to keep your systems running safely and efficiently.

Understanding Ceramic Fuses

What Are Ceramic Fuses?

Ceramic fuses act as protective devices designed to break the electrical circuit if excessive current flows through. Their structure comprises a robust, heat-resistant ceramic body that encases a thin wire or filament. When the current surpasses a specified level, the metal filament melts—effectively “blowing” the fuse and interrupting the circuit.

The ceramic shell remains intact under high temperatures, making these fuses suitable for demanding environments and heavy-duty applications.

Why Are They Used?

The principal advantage of ceramic fuses lies in their sturdy construction and high heat resistance. Unlike glass fuses, ceramic fuses do not shatter when overloaded. Instead, they are designed to withstand higher temperatures and to contain any arc caused by a blown filament, thus minimizing the potential for further damage or fire. These attributes make ceramic fuses ideal for appliances, industrial equipment, and situations where high-current protection is needed.

Common Applications

Ceramic fuses are ubiquitous in many everyday settings. They are routinely found in household appliances (like microwaves and dishwashers), automotive systems, industrial machinery, and even certain power tools. Their durability and ability to safely disconnect circuits make them a preferred choice in both residential and commercial environments.

Symptoms of a Blown Ceramic Fuse

Visual Signs

One of the first steps in diagnosing a blown ceramic fuse is a careful visual inspection. Although the opaque body often makes it hard to see the internal filament, you can still look for telltale signs. Discoloration or dark scorch marks around the fuse ends may indicate overheating or electrical arcing. In cases where the ceramic casing has a visible window, a broken or melted wire may be visible inside.

Electrical Malfunctions

A blown ceramic fuse frequently manifests as device malfunctions. For example, an appliance might refuse to power on, electronic displays could remain blank, or lights may flicker or operate inconsistently. These irregularities often signal an interruption in the power circuit—one possible culprit being a blown fuse.

Odor Changes

Fuses that have blown due to an electrical fault sometimes emit unusual odors. If you detect a burnt or metallic smell coming from the device or its fuse compartment, this odor may be a byproduct of the fuse’s internal wire having melted. Such smells are strong indicators of a blown ceramic fuse and should prompt immediate investigation.

Required Tools and Safety Measures

Tools for Testing

To accurately test a ceramic fuse, a few basic tools are essential. A digital or analog multimeter is critical for measuring continuity and resistance. Additionally, you might need a screwdriver (to access fuse panels or compartments) and a flashlight for better visibility. Make sure your tools are in good working condition before beginning your inspection.

Safety Precautions

Before handling any fuse, safety should be your top priority. Always turn off and unplug the device or disconnect power at the breaker box before opening any electrical panel or removing a fuse. This reduces the risk of electric shock or further damage to the device.

Proper Handling

When removing or inspecting a ceramic fuse, handle it by the ends and avoid touching any exposed metal contacts. Use insulated tools if possible and wear protective gloves if available. Treat each fuse as if the circuit could still be live until you are certain the power supply is disconnected.

Locating the Ceramic Fuse

Checking the Device Manual

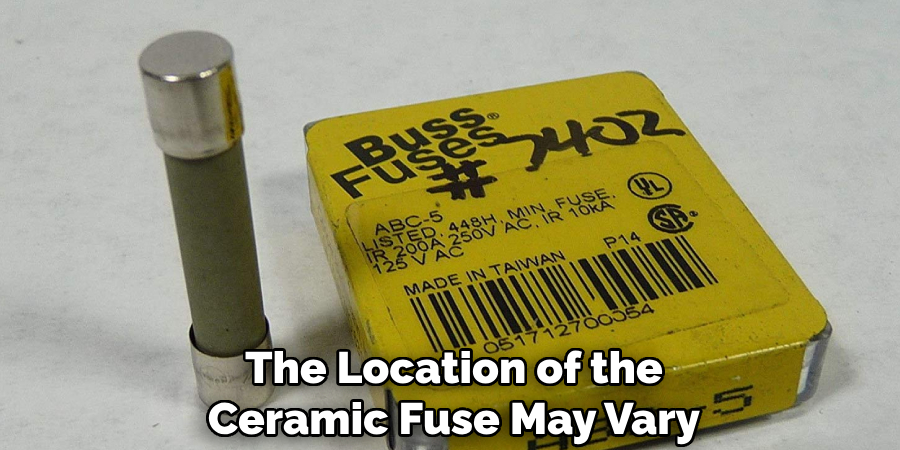

Each device is manufactured differently, so the location of the ceramic fuse may vary. Consult the user manual or technical documentation for your appliance or system. These materials typically contain diagrams or instructions indicating exactly where to find internal or accessible fuses.

Opening the Fuse Box

Many fuses are housed in dedicated fuse boxes. When opening a fuse box, determine if your fuse is a panel-mounted type (accessible from the outside) or an internal fuse (located within the device’s housing). Accessing internal fuses may require removing screws or panels; always secure any loose components and keep track of screws for reassembly.

Identifying the Fuse Type

When you locate a fuse, check for identifying marks—such as the amperage rating, voltage rating, and size. These details, usually stamped on the fuse or its holder, are crucial to ensure that any replacement fuse is of the correct specification for your device’s protection needs.

How to Tell if a Ceramic Fuse is Blown: Performing a Visual Inspection

Removing the Fuse

Once you’ve powered down and accessed the fuse compartment, carefully remove the ceramic fuse from its holder using an insulated tool or your fingers. Take care not to force it, as rough handling may cause additional damage to the holder or the device.

Examining the Fuse

Inspect the fuse outside of its holder. Look closely for visible signs such as cracks in the ceramic body, burn marks, or melted ends. If the fuse features a window, check for a broken or missing filament inside. A damaged or discolored fuse almost always requires replacement.

Comparing with a New Fuse

If you’re unsure about the status of the fuse, compare it directly to an identical new fuse. A blown fuse may appear damaged, discolored, or even rattle if the internal element has broken apart. This visual comparison can clarify whether the old fuse is the source of your device’s issues.

Testing the Ceramic Fuse with a Multimeter

Setting Up the Multimeter

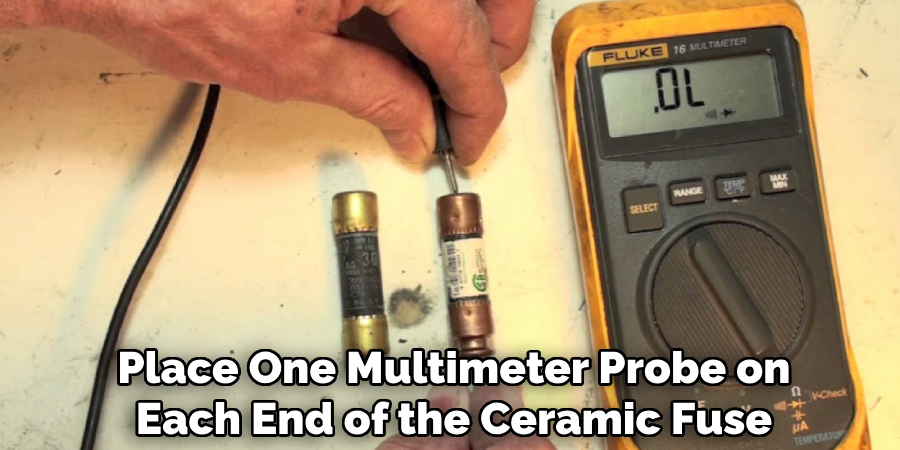

Begin by setting your multimeter to the continuity or resistance (ohms) mode. If your multimeter requires manual range selection, set it to the lowest resistance setting. Confirm that the device is powered off and unplugged before proceeding.

Testing for Continuity

Place one multimeter probe on each end of the ceramic fuse. If the fuse is intact, electrical current will pass through, and the multimeter will either beep (continuity mode) or show a resistance value very close to zero (ohms mode). If there is no audio signal or the reading shows infinite resistance, the fuse is blown and must be replaced.

Interpreting Results

An intact ceramic fuse will display continuity, reassuring you that it remains functional. A lack of continuity, or a high resistance reading, confirms that the fuse element inside has been broken and the fuse is no longer operational. Use this objective test as your definitive blow/no-blow indicator.

What to Do If the Fuse Is Blown

Purchasing a Replacement

If your ceramic fuse testing confirms a blown component, purchase a replacement that matches the original’s specifications—especially the voltage and amperage ratings. Many hardware stores, electronics suppliers, and online retailers offer a wide range of ceramic fuses suitable for different applications.

Installing the New Fuse

Before installing the replacement, double-check that all power sources remain disconnected. Insert the new ceramic fuse into the holder, making sure it sits securely and matches the orientation of the original. Secure any housing or covers you may have removed during the inspection.

Testing After Replacement

Once the new fuse is installed, reconnect power and test the device or system. The device should operate as intended. If it doesn’t, re-examine your installation or consult a professional, as other underlying problems may exist.

Preventive Measures to Avoid Fuse Blowing

Avoiding Overloads

Excessive electrical loads are a common cause of blown ceramic fuses. Avoid plugging too many high-power devices into the same circuit, and always ensure that your equipment does not exceed the rated capacity of the fuse.

Regular Device Maintenance

Perform regular maintenance checks on appliances and electrical systems. Look for frayed wires, loose connections, and worn components. Timely repairs can prevent shorts or overloads that trip fuses repeatedly.

Using Surge Protection

Voltage spikes, often caused by storms or unstable supply, can easily blow a fuse. Install surge protectors or uninterruptible power supplies (UPS) in areas where sensitive or expensive equipment operates. These devices can absorb and redirect excess energy, preventing sudden fuse failures.

When to Consult a Professional

Repeated Blown Fuses

If fuses keep blowing even after careful replacement and troubleshooting, this may indicate a persistent electrical fault. In such cases, professional help is advised to diagnose and repair the root cause.

Complex Electrical Systems

For complex or unfamiliar systems, professional electricians have the expertise and equipment needed to safely inspect, test, and replace fuses. Never attempt repairs that are beyond your skill level or that could put you at risk.

Safety Risks

Safety should always take precedence. Contact a professional if you feel unsafe, encounter unusual wiring, or cannot fully disconnect power from a device or circuit. Electrical work carries inherent risks and should not be taken lightly.

Conclusion

Knowing how to tell if a ceramic fuse is blown is an essential skill for anyone working with electrical appliances, vehicles, or machinery. Start with a careful visual inspection and use a multimeter for accurate testing. Always prioritize safety by disconnecting power before inspection or replacement, and handle all components with care.

By following the steps in this guide, you can quickly diagnose and resolve fuse-related issues, prolong the life of your equipment, and avoid unnecessary repairs or hazards. Remember, when in doubt, consult a qualified electrician to ensure safety and proper function—mastering the basics of ceramic fuse testing keeps your electrical systems safe and working efficiently.

Specialization:

- Master of wheel-throwing, hand-building, and advanced glazing techniques

- Focus on creating both functional pottery and decorative art pieces

Recognition:

- Celebrated by collectors and art enthusiasts for creating one-of-a-kind pieces that blend artistry with functionality

- Participates in local and national exhibitions, earning accolades for his innovative designs and craftsmanship

Passion:

- Deeply committed to exploring and pushing the boundaries of ceramic artistry

- Continuously experiments with new materials, firing techniques, and artistic concepts to evolve his craft

Personal Philosophy:

- Believes in the transformative power of art, aiming to evoke emotions and connections through his ceramic creations

- Advocates for sustainability in ceramics, using eco-friendly materials and practices whenever possible